Inspection & Testing

Our testing process is one part of our quality commitment plan. It uses ISO9001’s quality standard to comprehensively analyze our products in order to reduce the risk of electronic components in supply chain. All our products must undergo our wide-ranging testing process before they are sold or consigned and prepared for the shipment.

Incoming quality Inspection:

☞ External Visual Inspection

For all warehousing items, we will perform visual inspection and make detailed inspection records.

● Manufacturer, Part Number, quantity, date code verification, RoHS

● Manufacturer’s datasheet and specification verification

● Barcode scan testing

● Packaging inspection, whether it is intact/whether it has the original factory seal

● Refer to quality control database, inspect label/logo, whether encoded logo is clear

● Moisture Sensitivity Level confirmation (MSL) - vacuum seal situation & humidity indicator and specifications (HIC) LGG

● Physical condition review (weight belt, scratch, trimming)

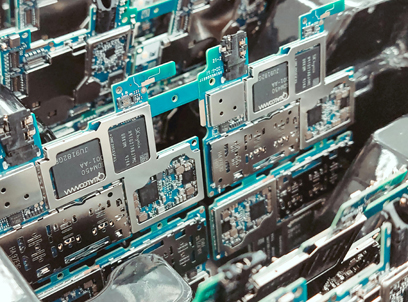

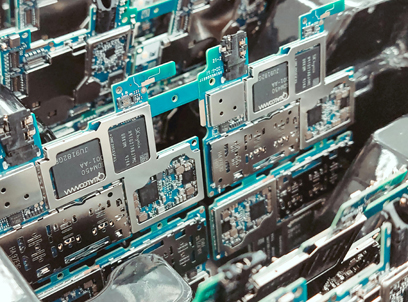

☞ Chip Function Inspection

All materials found to be suspected in the appearance inspection, or materials supplied by the "first-tier supplier" in the supplier channel non-system, must be engineered

● Material testing of dimensions and size, packaging situation

● Whether the material’s exterior pins are deformed, and whether they are oxidized

● Screen printing/surface inspection, check original factory specifications, whether screen printing is clear, whether it is identical with the original factory specifications

● Weight inspection

● Simple electric performance testing:DC/AC voltage, AC/DC current, 2- and 4-wire resistance, diode, continuity, frequency, period

● Summary analysis report